|

11. Hologram

drying

Hologram

drying operation is considered in a separate lesson,

since special attention should

be paid to non-obvious processes taking place by

drying and to influence of the drying operation

on the hologram quality. It can be very pity when

after so labour-intensive work relating to recording

and chemical treatment of the hologram and after

completion of the last operation you'll see on the

hologram not good-looking colored stains and spots

which sharply worsen image quality (see photo).

And the most unpleasant point consists in the fact

that these defects are unrepairable even if you

repeat the hologram drying operation. since special attention should

be paid to non-obvious processes taking place by

drying and to influence of the drying operation

on the hologram quality. It can be very pity when

after so labour-intensive work relating to recording

and chemical treatment of the hologram and after

completion of the last operation you'll see on the

hologram not good-looking colored stains and spots

which sharply worsen image quality (see photo).

And the most unpleasant point consists in the fact

that these defects are unrepairable even if you

repeat the hologram drying operation.

You'll probably be astonished if we tell you that

as a matter of fact this operation can't be called

drying operation in the strict sense of this term.

In reality the purpose of this operation is removal

of water only from the hologram surface. And namely

the remains of water on the emulsion layer surface

cause the above-mentioned defects. Water inside

the emulsion layer evaporates gradually and doesn't

cause any harm to the hologram.

It

may seem strange but the emulsion gelatinous layer

of the photographic plate partly has hydrophobic

properties - it repels water. You can easily make

sure of this while looking how water flows down

from the hologram by chemical treatment. Water is

gathered into separate streams and drops which remain

on the photographic plate surface even if you keep

it vertically over the tray. Mechanisms of water

(and water solutions) penetration into hydrophobic

emulsion layer and deformations of the emulsion

layer by surface water drying aren't yet found out

in details but it's obvious that just the remains

of these streams and drops are the main reasons

of colored stains on the hologram.

For uniform removal of surface water it's possible

to add the so-called surface-active substances (SAS)

into water. SAS always contain in shampoos and detergents.

They increase hydrophilic properties of the emulsion

layer and facilitate water flowing down from the

photographic plate. But this process proceeds slow

(it takes several hours) and drying quality is heavily

deteriorated because of dust particles, small glass

splinters and suspension from running water which

stick to emulsion layer surface. Colored stains

inevitably appear around every such small particle.

More rapid and reliable method of the hologram drying

is drying using ethyl alcohol. A research worker

S. Mc Grew was one of the first who paid attention

to peculiarities of alcohol drying of holograms

on dichromated gelatin (DCG). He discovered that

the alcohol penetrating into emulsion layer displaces

water from it (this process is called "dehydratation")

only in the direct vicinity from the emulsion layer

surface. As though a thin "crust" of dry

gelatin is formed which prevents going out and evaporation

of water located inside the emulsion layer. This

circumstance promotes carrying-out high-quality

hologram drying.

For alcohol saving three alcohol

solutions with 50%, 80% and 100% alcohol concentration

are usually used. Accurately take a photographic

plate from the tray with running water and after

water flowing down place it into the tray with 50%

alcohol solution. For removal of surface water raise

one edge of the hologram from the tray under angle

of 40-50 degrees and let alcohol flow down during

10-15 seconds. Alcohol drags water behind it from

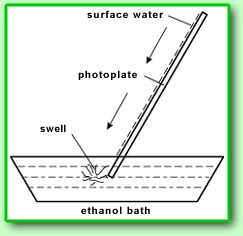

the photographic plate surface. If you use trays

of transparent plastic you can see faint transparent

inhomogeneities - swells (see photo) near the lower

edge of the hologram. This is water flowed down

from the photographic plate and not yet dissolved

in alcohol. Having raised the photographic plate

out of the tray 4-5 times in such a way you can

make certain that the number of strias becomes progressively

less - that is water leaves the photographic plate

surface. This procedure is repeated in every tray

successively raising alcohol concentration. For alcohol saving three alcohol

solutions with 50%, 80% and 100% alcohol concentration

are usually used. Accurately take a photographic

plate from the tray with running water and after

water flowing down place it into the tray with 50%

alcohol solution. For removal of surface water raise

one edge of the hologram from the tray under angle

of 40-50 degrees and let alcohol flow down during

10-15 seconds. Alcohol drags water behind it from

the photographic plate surface. If you use trays

of transparent plastic you can see faint transparent

inhomogeneities - swells (see photo) near the lower

edge of the hologram. This is water flowed down

from the photographic plate and not yet dissolved

in alcohol. Having raised the photographic plate

out of the tray 4-5 times in such a way you can

make certain that the number of strias becomes progressively

less - that is water leaves the photographic plate

surface. This procedure is repeated in every tray

successively raising alcohol concentration.

Immediately after termination of drying process

in a 100% alcohol it's possible to remove easily

the adhered small particles from the photographic

plate surface using a small soft brush wetted in

alcohol. This would be totally impossible before

alcohol drying. The rigid "crust" prevents

damage of gelatin layer. Begin to remove particles

moving from the upper edge of the hologram to the

lower edge following alcohol flowing down. Remove

only the biggest particles since very small particle

aren't visible on the hologram after alcohol drying

up. Nevertheless be very careful by removal of glass

splinters. The fact is that a touch of the brush

can lead to a deeper penetration of the sharp glass

splinter into gelatin layer. Therefore if the splinter

can't be removed after several attempts leave it

at its place. After alcohol drying up it possibly

will create a hardly noticeable point on the hologram.

After removal of small particles place the photographic

plate on the filter paper or ordinary tissue paper

under an angle. So the second step of drying process

begins - evaporation of water from the emulsion

layer.  This process is slowed down

through existence of dry "crust" but since

there is already no surface water and since the

volume of this water considerably exceeded water

volume inside the emulsion layer duration of the

drying process doesn't exceed half an hour. This process is slowed down

through existence of dry "crust" but since

there is already no surface water and since the

volume of this water considerably exceeded water

volume inside the emulsion layer duration of the

drying process doesn't exceed half an hour.

Image gradually appears on the hologram. More exactly

it is transformed from the infrared spectral region

into visible spectral region as the thickness of

the emulsion layer loosing water returns to the

original state. But the final image color won't

be red as laser radiation color any longer but will

be within the limits from orange to green color

depending on the humidity level in the room and

on the degree of the emulsion layer tanning. This

effect is connected with the fact that after fixing

and removal of not developed silver bromide the

emulsion layer thickness decreased slightly. Now

the hologram is ready for final decoration (see

photo).

References

1. S.P. Mc Grew "Color control in dichromated

gelatin reflection holograms", SPIE, v. 215,

1980, p.24-31.

2. S. Vorobyov "The sensitization of VR-P Russian

photoplates for recording pulsed holograms",

SPIE, v. 3358, 1997, p.67.

-->

|