|

9. Preparation

of chemical solutions

The

process of chemical processing of holograms is one

of the most critical steps in hologram making: first

of all, it is almost impossible to buy solutions

for chemical processing of holograms, you have to

prepare them by yourself. Quality of holograms depends

greatly upon accuracy of the chemical solution composition.

Holography as well as photography has a lot of methods

for chemical processing of holograms for different

types of photoplates and schemes of hologram recording

[1].

We are not going to consider extraordinary formulas

and methods. We'll examine a standard method of

PFG-03m photoplates chemical processing. You have

already studied that these photoplates have the

highest resolving power to register the finest interference

pattern of a reflect hologram recorded according

to Denisyuk's scheme. The main aim of the developing

process of Denisyuk's hologram is saving of this

interference pattern in the developed hologram.

Developer preparation

Usual photographic developers

referring to the type of "chemical" developers

are not suitable for this purpose. During developing

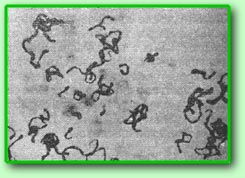

silver bromide microcrystals in the emulsion layer

of a photoplate turn into tangles of metallic silver.

Their size is equal or exceeds the size of the interference

pattern period (see fig.). For the same reason developed

negative films and photographic papers are black

- silver balls absorb light (!). It has nothing

to do with an ordinary silver plate. Usual photographic developers

referring to the type of "chemical" developers

are not suitable for this purpose. During developing

silver bromide microcrystals in the emulsion layer

of a photoplate turn into tangles of metallic silver.

Their size is equal or exceeds the size of the interference

pattern period (see fig.). For the same reason developed

negative films and photographic papers are black

- silver balls absorb light (!). It has nothing

to do with an ordinary silver plate.

So called "physical" developers are used

for developing super high resolution photoplates

PFG-03m. There is a special component in these developers.

It is ammonium thiocyanate. Ammonium thiocyanate

dissolves crystals of silver bromide.  Practically the same process

happens in the fixer, but in the developer atoms

of silver bromide being in the solution are reduced

to metallic silver and then they fall on silver

bromide microcrystals (this process is called diffusive

transfer). Kinetics of this complicated process

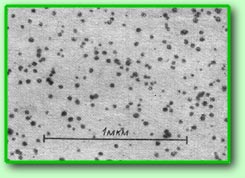

is such that after development compact grains of

metallic silver appear and their size is close to

the size of silver bromide (see fig.). As a result

the interference pattern of the developed hologram

is completely preserved. Practically the same process

happens in the fixer, but in the developer atoms

of silver bromide being in the solution are reduced

to metallic silver and then they fall on silver

bromide microcrystals (this process is called diffusive

transfer). Kinetics of this complicated process

is such that after development compact grains of

metallic silver appear and their size is close to

the size of silver bromide (see fig.). As a result

the interference pattern of the developed hologram

is completely preserved.

Let us consider composition of GP-2 developer which

was worked out by Russian scientist Usanov Y.E.

Formulation of GP-2 developer and its modification

GP-3 are given below.

|

GP-2

|

|

GP-3

|

Methylphenidone

0.2 g

Hydroquinone 5 g

Sodium sulfite, (Na2SO3)

100 g

(anhydrous)

Potassium hydroxide (KOH) 5 g

Ammonium thiocyanate (NH4SCN)

6 g

Water up to 1 l |

|

Methylphenidone

0.2 g

Hydroquinone 5 g

Sodium sulfite, (Na2SO3)

100 g

(anhydrous)

Potassium hydroxide (KOH) 25 g

Ammonium thiocyanate (NH4SCN)

45 g

Water up to 1 l |

You

can see the developers have the same composition,

the only difference is quantity of some chemicals.

Let us consider the purpose of each chemical in

a brief way.

1. Methylphenidone and hydroquinone are developing

substances. If they work together they are more

active than each taken separately.

2. Sodium sulfite prevents rapid oxidation of the

developing substances and stabilizes work of the

fixer. It provides fine-grain development since

microcrystals of silver bromide are partly dissolved.

3. Potassium hydroxide creates alkaline medium in

the developer. The developing substances can actively

work only in alkaline medium.

4. Ammonium thiocyanate is the most "holographic"

component of the developer. (It is not used in the

photographic developers). It actively dissolves

crystals of silver bromide and provides super fine-grain

development.

To prepare the developer it

is necessary to have all the mentioned chemicals,

a balance of 0.01 g accuracy, a thermometer of 0.1oC

accuracy, 2 retorts of 1l, a graduated cylinder

of 1 ml graduation, distilled water (see photo).

Cut several sheets of A4 paper in two and weight

out each chemical. You should put rubber gloves

on. Be very careful with potassium hydroxide. Avoid

its contact with your skin or clothes. To prepare the developer it

is necessary to have all the mentioned chemicals,

a balance of 0.01 g accuracy, a thermometer of 0.1oC

accuracy, 2 retorts of 1l, a graduated cylinder

of 1 ml graduation, distilled water (see photo).

Cut several sheets of A4 paper in two and weight

out each chemical. You should put rubber gloves

on. Be very careful with potassium hydroxide. Avoid

its contact with your skin or clothes.

It is known phenidone and methylphenidone are dissolved

in water badly but their dissolubility in the alkaline

solution is good. Pour 300 ml of water into a retort

and dissolve there potassium hydroxide. Add the

alkali by small portion and mix the solution by

a plastic stick thoroughly. Alkali dissolution in

water is an exothermic reaction (a reaction with

heat release). So that if you add all the alkali

weighed amount, the retort may be blown up because

of overheating. After the alkali has been dissolved

completely, dissolve phenidone. The solution will

become pinkish.

Pour 500 ml of water into the second retort and

then dissolve sodium sulfite and ammonium thiocyanate.

Ammonium thiocyanate has an unpleasant smell of

ammonia therefore you should work in a room with

good ventilation or under a hood. After all the

chemicals have been completely dissolved pour both

solutions together and mix them thoroughly and add

water to 1l. The prepared developer should be absolutely

transparent and have a significant smell of ammonia.

Filtrate the developer using a cotton wool tampon

and a funnel. Pour the developer into a bottle with

a hermetic stopper. Mark the bottle (name of the

developer and date of its production) and put it

in the refrigerator. The developer can be stored

in a refrigerator not less than a month.

Wash the retorts, the funnel and the plastic stick

carefully.

If the developer is turbid or it is brown or it

has another color or if there are flakes or sediment,

or there is no smell of ammonia, it means that one

of the chemicals is not suitable for usage. Check

if the chemical names and date of their storage

life are correct and if their weighed amounts are

accurate. Then try again to prepare the developer.

Fixer preparation

To

protect the developed hologram from light influence

(light can cause darkening), unexposed microcrystals

of silver bromide should be removed from the emulsion

layer. For this purpose a photoplate is processed

by a fixing solution where the rest microcrystals

of silver bromide are dissolved and removed from

the emulsion layer. The simplest neutral fixer is

used to fix PFG-03 photoplates. Microcrystals of

silver bromide have very small dimensions and their

dissolving in the fixer takes several seconds. Some

specialists even convince that it is not necessary

to fix the photoplates in GP-2 or GP-3 after their

developing since the most part of silver bromide

has been already dissolved in the developer. It

is right, but we should use the fixer to make the

process reliable.

Here is the fixer formula:

Sodium thiosulfate (hyposulfite)

(Na2S2O3*5H2O)

150 g

Na2SO3 (anhydrous)

50 g

Water up to 1l |

Dissolve

sodium sulfite in 700 ml of water. Then dissolve

sodium thiosulfate and increase the solution volume

to 1l, using water. Thiosulfate dissolving is an

endothermic reaction (a reaction with heat absorption),

so it is desirable to warm up water for this solution

to 40-50oC. The ready fixer is absolutely

transparent and it does not have any smell. Filter

the solution, pour it into a bottle with a hermetic

stopper, mark and put it in the refrigerator.

Wash the retorts, the funnel and the plastic stick

carefully.

Preparation

of alcohol solutions for hologram drying

Ethyl

alcohol solutions are used for qualitative drying

of holograms. It is possible to dry a hologram in

100% alcohol at once. But in this case alcohol will

absorb water rapidly and quality of drying will

worsen rapidly too. Therefore to save alcohols,

drying is executed by three steps - successively

in 50%, 80% and 100% alcohol. (To be precise, the

usual alcohol has 96% concentration). Prepare the

alcohol solutions in the following sequence:

50% alcohol - pour 500 ml of water and 500 ml of

alcohol and mix,

80% alcohol - pour 200 ml of water and 800 ml of

alcohol and mix.

Pour the alcohol solutions into hermetic bottles,

mark and put them in the refrigerator.

Wash the retorts, the funnel and the plastic stick

with running water carefully.

References

1. H.I. Bjelkhagen "Silver-Halide Recording

Materials (for Holography and Their Processing)",

Springer Series, USA, 1993.

2. T.H. James "The Theory of the Photographic

Process", Macmillan Publishing Co., New York,

1977.

3. Usanov Y.E. "Influence of the Developer

Composition upon the Holographic Image Properties",

Recording Mediums for Holography (Collected Articles),

Science, Leningrad, 1975, p. 98.

-->

|